L-Raider

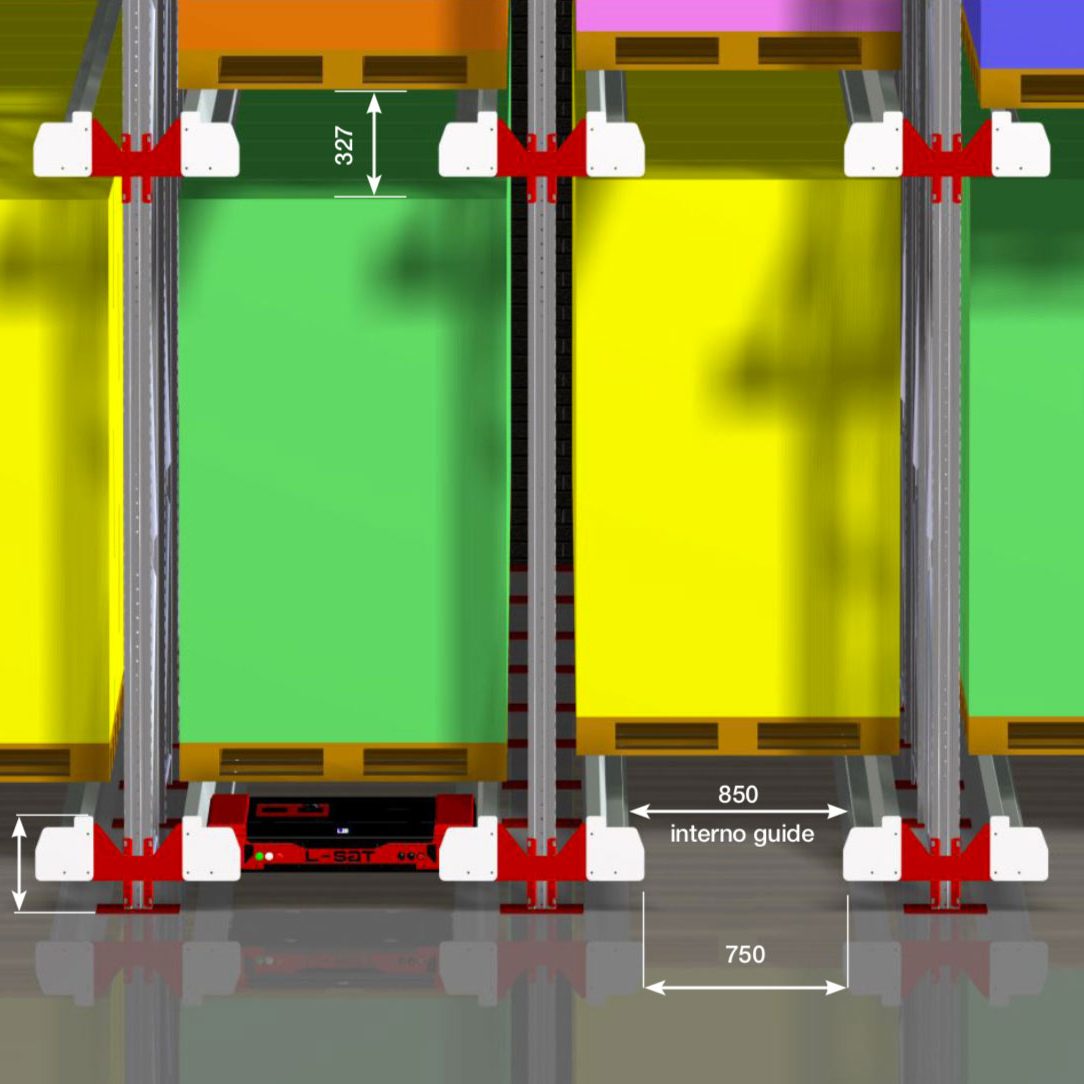

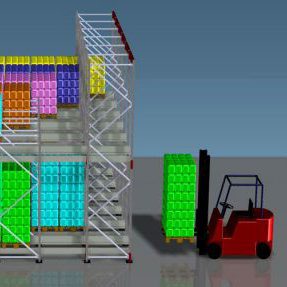

Warehouse automation offers higher efficiency, speed and convenience L-RAIDER is an automatic system that exploits the shelving structures, as a handling device and as the stored pallets’ support, optimising space management. L-RAIDER equips a warehouse for storing large quantities of materiai inside appropriately sized pallet racks, significantly reducing the space required compared to a conventional […]

Learn more